The construction and industrial sectors in Houston heavily rely on cranes for various lifting and transportation tasks. While cranes are indispensable for these industries, they also pose significant safety risks. Crane accidents can lead to severe injuries, fatalities, and substantial property damage. In recent years, the integration of advanced robotics and artificial intelligence (AI) has emerged as a promising solution to mitigate these risks and enhance overall safety in crane operations.

This article explores the role of advanced robotics and AI in mitigating crane accident risks in Houston. It examines the technological advancements in robotics and AI, their application in crane operations, and the potential benefits and challenges associated with their implementation.

Technological Advancements in Robotics and AI

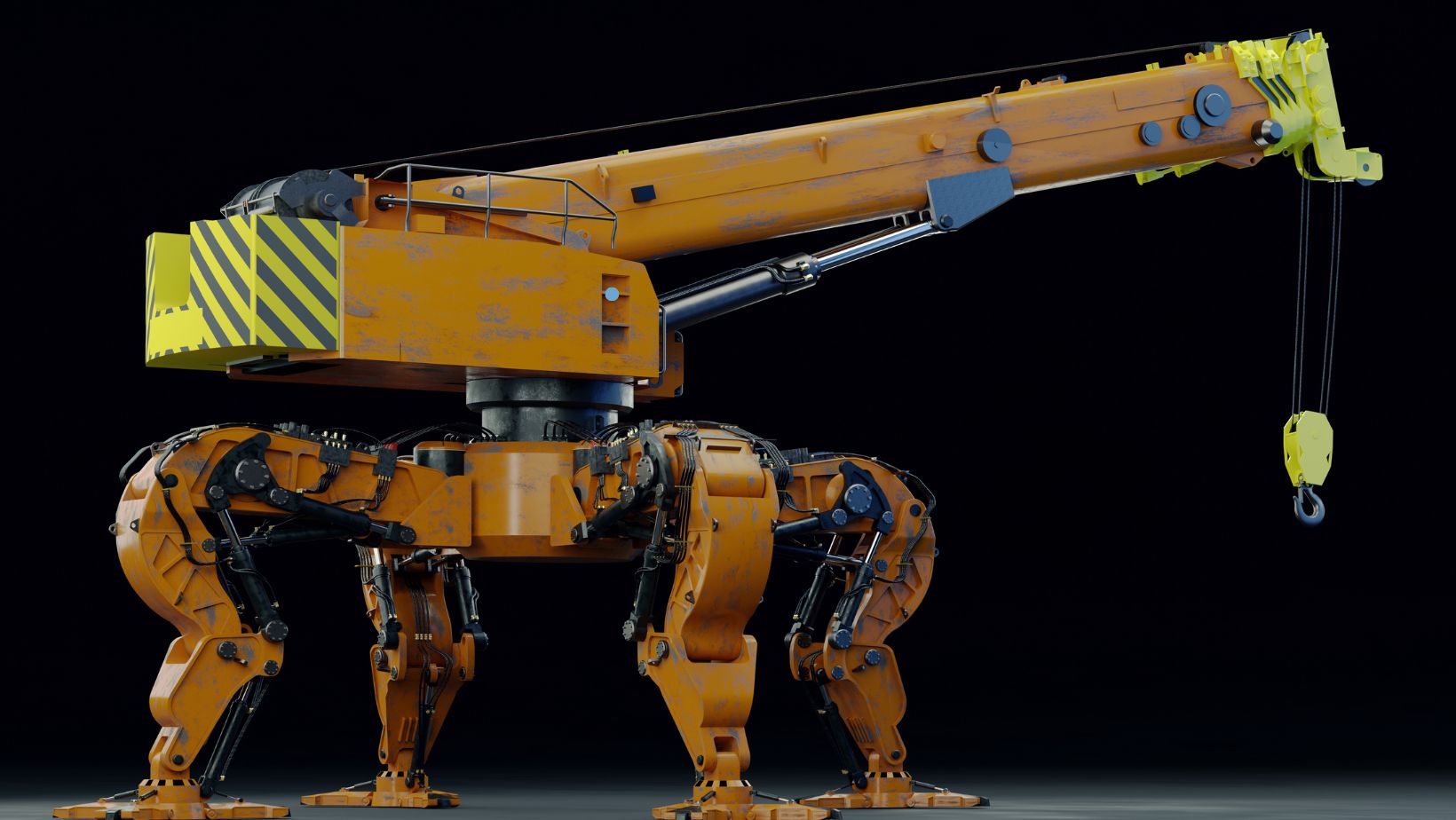

Robotics in Crane Operations

Robotics technology has made significant strides in automating and optimizing crane operations. Modern cranes equipped with robotic systems can perform precise movements, reduce human error, and handle complex lifting tasks more safely. Robotic arms, sensors, and control systems enhance the precision and efficiency of crane operations, minimizing the risk of accidents caused by human error.

AI and Machine Learning

AI and machine learning algorithms are being used to predict potential hazards and optimize crane operations. These technologies can analyze vast amounts of data from sensors and cameras to identify patterns and predict equipment failures or unsafe conditions. AI systems can also assist in real-time decision-making, providing operators with critical information to prevent accidents.

Benefits of Advanced Robotics and AI

Enhanced Safety

One of the most significant benefits of integrating advanced robotics and AI in crane operations is the enhanced safety they provide. By automating repetitive and dangerous tasks, robotics can reduce the likelihood of human error, which is a leading cause of crane accidents. Robotic systems can perform tasks with a level of precision and consistency that human operators cannot match, thereby reducing the risk of accidents caused by operator fatigue or distraction.

Predictive Maintenance

AI and machine learning can play a crucial role in predictive maintenance, a proactive approach to identifying potential equipment failures before they occur. By analyzing data from sensors embedded in cranes, AI systems can detect signs of wear and tear or other issues that might lead to equipment failure. This allows maintenance teams to address problems before they result in accidents, improving the overall safety and reliability of crane operations.

Real-Time Monitoring and Decision-Making

Advanced robotics and AI enable real-time monitoring and decision-making in crane operations. Sensors and cameras installed on cranes can provide continuous data on the crane’s condition and its surroundings. AI algorithms can analyze this data in real time, alerting operators to potential hazards and suggesting corrective actions. This capability can prevent accidents by ensuring that operators are aware of and can respond to issues as they arise.

Improved Training and Simulation

Robotics and AI can also enhance the training and simulation of crane operators. Virtual reality (VR) and augmented reality (AR) technologies can create realistic training environments where operators can practice and hone their skills without the risk of real-world accidents. AI-driven simulators can provide personalized feedback and adapt training scenarios based on the operator’s performance, ensuring that they are well-prepared for the challenges of crane operations.

Challenges and Considerations

High Implementation Costs

One of the primary challenges of integrating advanced robotics and AI in crane operations is the high initial cost. The acquisition and installation of robotic systems and AI technologies require significant investment, which can be a barrier for many companies. Additionally, there are ongoing costs associated with maintaining and updating these technologies.

Workforce Adaptation

The introduction of advanced robotics and AI in crane operations may face resistance from workers who are accustomed to traditional methods. Workers may be concerned about job security and the need to adapt to new technologies. It is essential for companies to address these concerns through effective communication, training programs, and reassurances about job roles and opportunities for upskilling.

Reliability and Security

Ensuring the reliability and security of AI systems is another critical consideration. AI and robotic systems must be robust and reliable to prevent malfunctions that could lead to accidents. Additionally, these systems must be secure from cyber-attacks that could compromise their operation and safety. Implementing strong cybersecurity measures and regular system checks are essential to maintaining the integrity of AI and robotic systems.

Regulatory and Compliance Issues

The integration of advanced robotics and AI in crane operations must comply with existing safety regulations and standards. Regulatory bodies may need to update or develop new guidelines to address the unique challenges and risks associated with these technologies. Companies must stay informed about regulatory changes and ensure that their use of AI and robotics complies with all relevant standards.

Case Studies and Examples

Autonomous Cranes in Construction

Several construction companies have begun implementing autonomous cranes equipped with advanced robotics and AI. These cranes can perform lifting tasks with minimal human intervention, using sensors and cameras to navigate and operate safely. By automating these tasks, companies have reported a significant reduction in accidents and improved efficiency on construction sites.

AI-Driven Predictive Maintenance

A leading crane manufacturer has developed an AI-driven predictive maintenance system that monitors the condition of cranes in real-time. By analyzing data from sensors embedded in the cranes, the AI system can predict when components are likely to fail and schedule maintenance accordingly. This proactive approach has led to a decrease in unexpected equipment failures and associated accidents.

Virtual Reality Training for Crane Operators

A training facility for crane operators has integrated virtual reality (VR) and AI technologies into its programs. Operators can practice in realistic virtual environments, receiving immediate feedback and adjusting their techniques based on AI-driven analysis. This approach has enhanced the training experience, leading to better-prepared operators and a reduction in crane-related accidents.

Future Directions

Integration with Internet of Things (IoT)

The integration of advanced robotics and AI with the Internet of Things (IoT) presents exciting possibilities for further enhancing crane safety. IoT devices can provide real-time data on environmental conditions, equipment status, and operator performance. By combining this data with AI algorithms, companies can gain deeper insights into crane operations and implement more effective safety measures.

Advanced Robotics

The development of more sophisticated robotic systems will continue to improve crane safety. Innovations such as collaborative robots (cobots) that work alongside human operators and advanced autonomous systems that can handle complex tasks independently will further reduce the risk of accidents and enhance operational efficiency.

AI-Enhanced Decision Support Systems

Future advancements in AI will lead to even more powerful decision support systems for crane operations. These systems will provide operators with real-time insights and recommendations, helping them to make better decisions and avoid potential hazards. By continuously learning from data, AI systems will become increasingly adept at predicting and preventing accidents.